Unique Applications of the Best Vacuum Forming Plastic Sheets in Modern Design

In the ever-evolving landscape of modern design, vacuum forming plastic sheets have emerged as a pivotal tool, revolutionizing the way designers approach product development and prototyping. According to a recent report by Smithers Pira, the global market for vacuum forming plastics is projected to reach over $14 billion by 2025, driven by the growing demand for lightweight, versatile, and durable materials across various industries. These sheets not only allow for intricate shapes and designs but also offer cost-effective solutions for mass production, making them indispensable in sectors such as automotive, packaging, and consumer goods.

The unique applications of vacuum forming plastic sheets provide designers with the creative freedom to innovate and develop products that cater to contemporary aesthetic and functional needs, highlighting their significance in shaping the future of design.

Applications of Vacuum Forming Plastic Sheets in Architecture and Interior Design

Vacuum forming plastic sheets have revolutionized architectural and interior design, offering versatility and innovation that align with contemporary aesthetics and functionality. According to a report by Smithers Pira, the global market for vacuum forming is projected to grow at an annual rate of 5.5%, reflecting the increasing demand for lightweight and durable materials in construction. Designers leverage these sheets to create complex shapes and structures that were once unattainable with traditional materials.

In interior design, vacuum forming plastic sheets are often used for unique wall coverings, custom furniture, and fixtures that enhance aesthetic appeal while providing practical solutions. Their ability to mimic the appearance of more expensive materials at a fraction of the cost makes them an attractive option. Moreover, these sheets are produced with eco-friendly considerations in mind, as many are made from recyclable thermoplastics. Industry insights suggest that integrating vacuum forming into interior design not only adds a modern flair but also contributes to sustainable practices in the built environment, paving the way for innovative and responsible design solutions.

Unique Applications of the Best Vacuum Forming Plastic Sheets in Modern Design

| Application Area | Material Type | Key Benefits | Examples |

|---|---|---|---|

| Architecture | Acrylic | Lightweight, UV resistant, High clarity | Skylights, Curved walls |

| Interior Design | Polycarbonate | Impact resistant, Versatile, Lightweight | Room dividers, Decorative panels |

| Furniture Design | PVC | Durable, Easy to clean, Cost-effective | Table tops, Chairs |

| Lighting Design | PETG | Good light transmission, Chemical resistant | Light fixtures, Lampshades |

| Exhibits and Displays | HIPS | Easily printable, Versatile shapes | Trade show displays, Retail fixtures |

Innovative Uses of Vacuum Forming Plastics in Product Packaging and Branding

Vacuum forming plastics have transformed product packaging and branding with their versatility and adaptability. According to a recent report by Freedonia Group, the demand for plastic packaging is projected to reach $250 billion globally by 2024, driven largely by its lightweight and customizable nature. Companies are increasingly utilizing vacuum formed products to create eye-catching packaging that enhances brand visibility and consumer engagement. Innovative designs can be achieved through vacuum forming, allowing brands to create distinctive shapes and sizes that stand out on retail shelves.

Tips for effective packaging design include incorporating transparent vacuum formed elements to showcase the product itself, which can increase perceived value. Additionally, businesses should consider sustainability; opting for recyclable plastic materials can significantly enhance brand reputation and appeal to environmentally-conscious consumers. With consumer preferences shifting, reports from Smithers Pira highlight that about 58% of consumers are willing to pay more for sustainable packaging options, making vacuum forming an attractive choice.

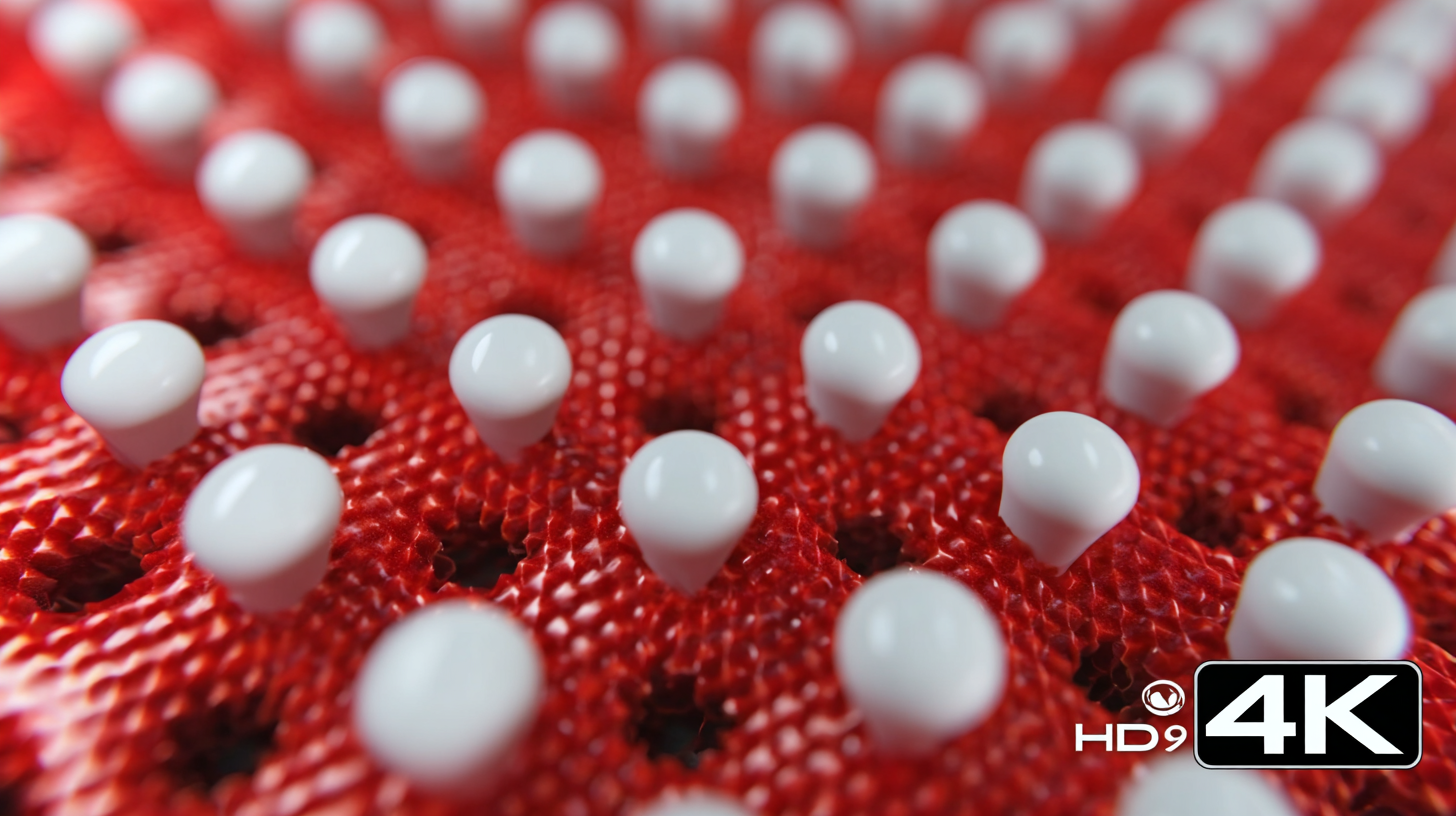

Brands can also leverage vacuum forming to create interactive packaging experiences. By integrating unique textures and shapes, companies can engage consumers more effectively, turning ordinary packaging into a crucial marketing tool. The ability to design packaging that not only protects but also captivates is a game-changer in today's competitive market, as noted in the latest market insights from MarketsandMarkets, which emphasizes the importance of aesthetic appeal in consumer purchasing decisions.

The Role of Vacuum Forming in Automotive Design and Customization Techniques

Vacuum forming is increasingly pivotal in automotive design, offering innovative customization techniques that elevate both functionality and aesthetics. By employing vacuum forming techniques, manufacturers can create complex shapes and lightweight components, tailored to the unique needs of each vehicle model. This process not only enhances the design flexibility but also contributes significantly to cost reduction and material efficiency, making it a preferred choice in the automotive industry.

Vacuum forming is increasingly pivotal in automotive design, offering innovative customization techniques that elevate both functionality and aesthetics. By employing vacuum forming techniques, manufacturers can create complex shapes and lightweight components, tailored to the unique needs of each vehicle model. This process not only enhances the design flexibility but also contributes significantly to cost reduction and material efficiency, making it a preferred choice in the automotive industry.

As the vacuum casting market is poised to grow from USD 2.73 billion in 2025 to USD 4.57 billion by 2033, at a compound annual growth rate (CAGR) of 6.67%, it highlights the growing demand for advanced manufacturing processes in automotive engineering. The rise of additive manufacturing complements this trend, enabling the industry to achieve sustainable development goals through innovative, cost-effective solutions. As automakers increasingly seek to reduce weight and improve fuel efficiency, vacuum forming proves to be essential in creating durable and versatile components that meet contemporary demands.

Sustainability in Vacuum Forming: How Plastic Sheets Reduce Waste in Manufacturing

Vacuum forming has emerged as a vital process in modern design, particularly due to its emphasis on sustainability. By utilizing plastic sheets that can be recycled and repurposed, manufacturers significantly reduce waste produced during fabrication. Traditional manufacturing methods often involve intricate processes that generate excess material, but vacuum forming streamlines production by allowing for precise shaping of sheets with minimal leftovers. This not only conserves resources but also diminishes the environmental impact associated with plastic waste.

Moreover, the use of advanced plastic sheets in vacuum forming contributes to innovative designs while adhering to eco-friendly practices. These sheets can be engineered to have varying properties, allowing designers to select materials that suit specific applications, from lightweight packaging to durable infrastructure components. This versatility enables companies to implement sustainable solutions without compromising on quality or functionality. As industries increasingly prioritize environmentally responsible manufacturing, the unique applications of vacuum forming and its recyclable plastic sheets position themselves as a cornerstone of modern design, promoting a circular economy.

Unique Applications of the Best Vacuum Forming Plastic Sheets

This chart illustrates the percentage of different applications of vacuum forming plastic sheets in various industries, highlighting their role in sustainability by reducing waste in manufacturing processes.

Trends in Consumer Electronics: Vacuum Forming Plastic Sheets for Enhanced Aesthetics and Functionality

In today’s rapidly evolving consumer electronics landscape, the application of vacuum forming plastic sheets is becoming increasingly prevalent. As designers emphasize aesthetics and functionality, materials like PETG offer unique solutions that are reshaping product development. With the PETG market projected to reach a valuation of USD 2.94 billion by 2025, it is clear that manufacturers are recognizing the advantages of this versatile thermoplastic, including its clarity, impact resistance, and ease of fabrication. This allows for innovative designs that not only attract consumers but also meet the highest standards of durability.

As consumer expectations rise, with 70 percent prioritizing quality and longevity over price, the role of vacuum forming in product design cannot be overstated. These plastic sheets enable the creation of intricate, lightweight components that can enhance the user experience. The trend toward composite materials in automotive applications echoes this shift, demonstrating that durability and aesthetic appeal can coexist, leading to a more robust product offering. Embracing these trends will be crucial for brands looking to stay ahead in the competitive landscape of consumer electronics.