How to Efficiently Use Vacuum Forming Plastic Sheets for Your Manufacturing Needs: Key Insights and Data

In the world of manufacturing, the utilization of vacuum forming plastic sheets has emerged as a game-changing technique for creating a wide spectrum of products efficiently and cost-effectively. This innovative process allows manufacturers to mold thermoplastic materials into intricate shapes with precision, catering to diverse industries such as automotive, consumer goods, and packaging. Understanding how to efficiently use vacuum forming plastic sheets is crucial for maximizing productivity and ensuring product quality. By exploring key insights and essential data surrounding this method, manufacturers can make informed decisions that enhance operational workflows and reduce waste. Whether you're a seasoned professional or new to the field, mastering the use of vacuum forming plastic sheets can significantly elevate your manufacturing capabilities, from conceptualization to final production stages.

Understanding Vacuum Forming and Its Applications in Manufacturing

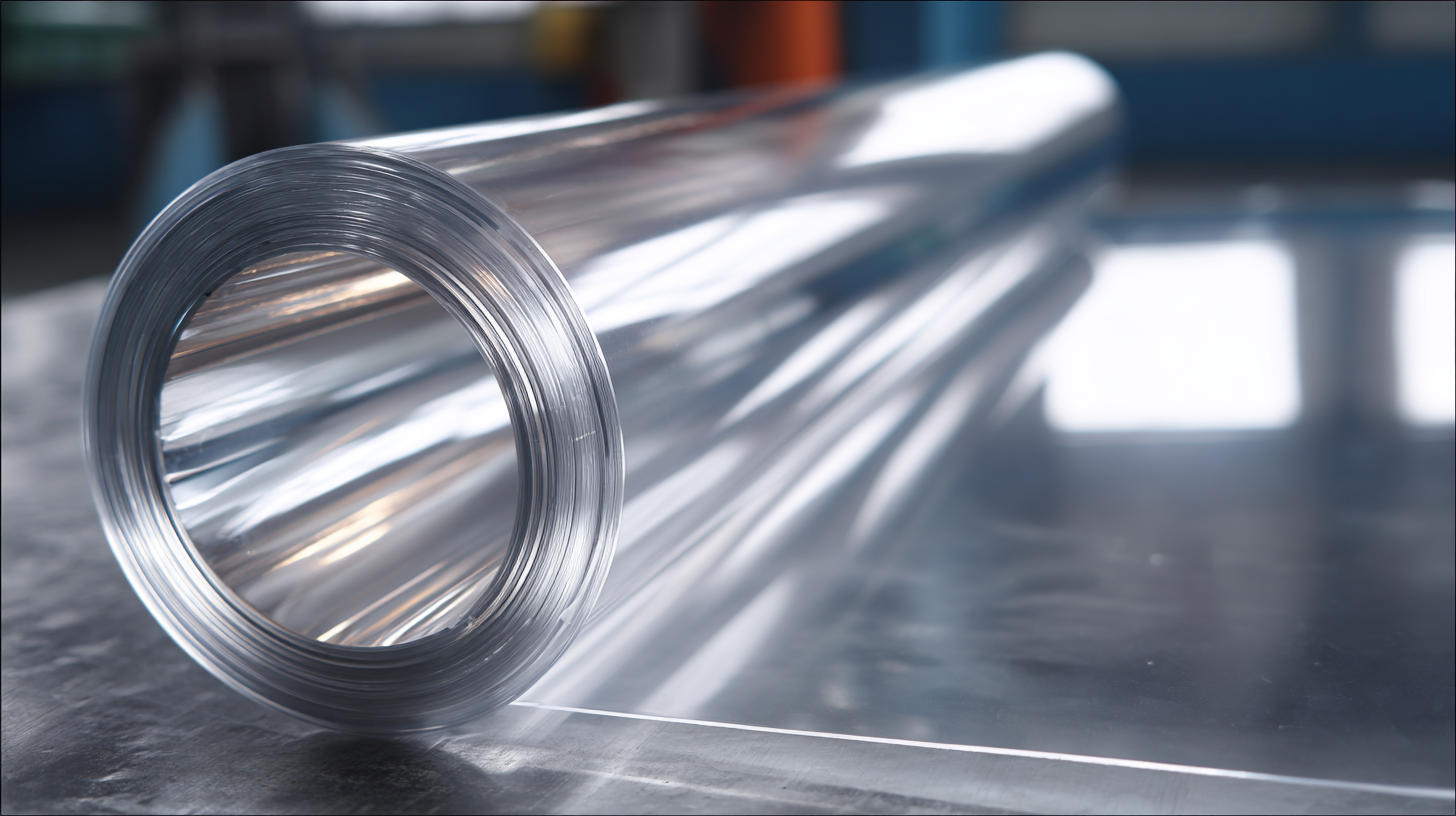

Vacuum forming is a widely used manufacturing process that transforms plastic sheets into various shapes and designs through the application of heat and vacuum pressure. This technique begins with heating a thermoplastic sheet until it becomes pliable, after which it is stretched over a mold. A vacuum is then applied, pulling the sheet tightly against the mold and ensuring that it takes on the desired shape. This process allows for efficient production of complex and detailed components, making it an ideal choice for various industries, including automotive, packaging, and consumer products.

The applications of vacuum forming are diverse and continually expanding. It is commonly employed in producing packaging materials, such as clamshells and trays, due to its ability to create lightweight yet sturdy designs. Additionally, in the automotive sector, vacuum forming is used to manufacture interior panels, dashboards, and other components that require both durability and aesthetic appeal. Moreover, the versatility of vacuum forming enables manufacturers to create prototypes quickly, allowing for rapid iterations in product design. This adaptability makes vacuum forming an invaluable technique in modern manufacturing, where efficiency and innovation are paramount.

Choosing the Right Plastic Sheets for Vacuum Forming Projects

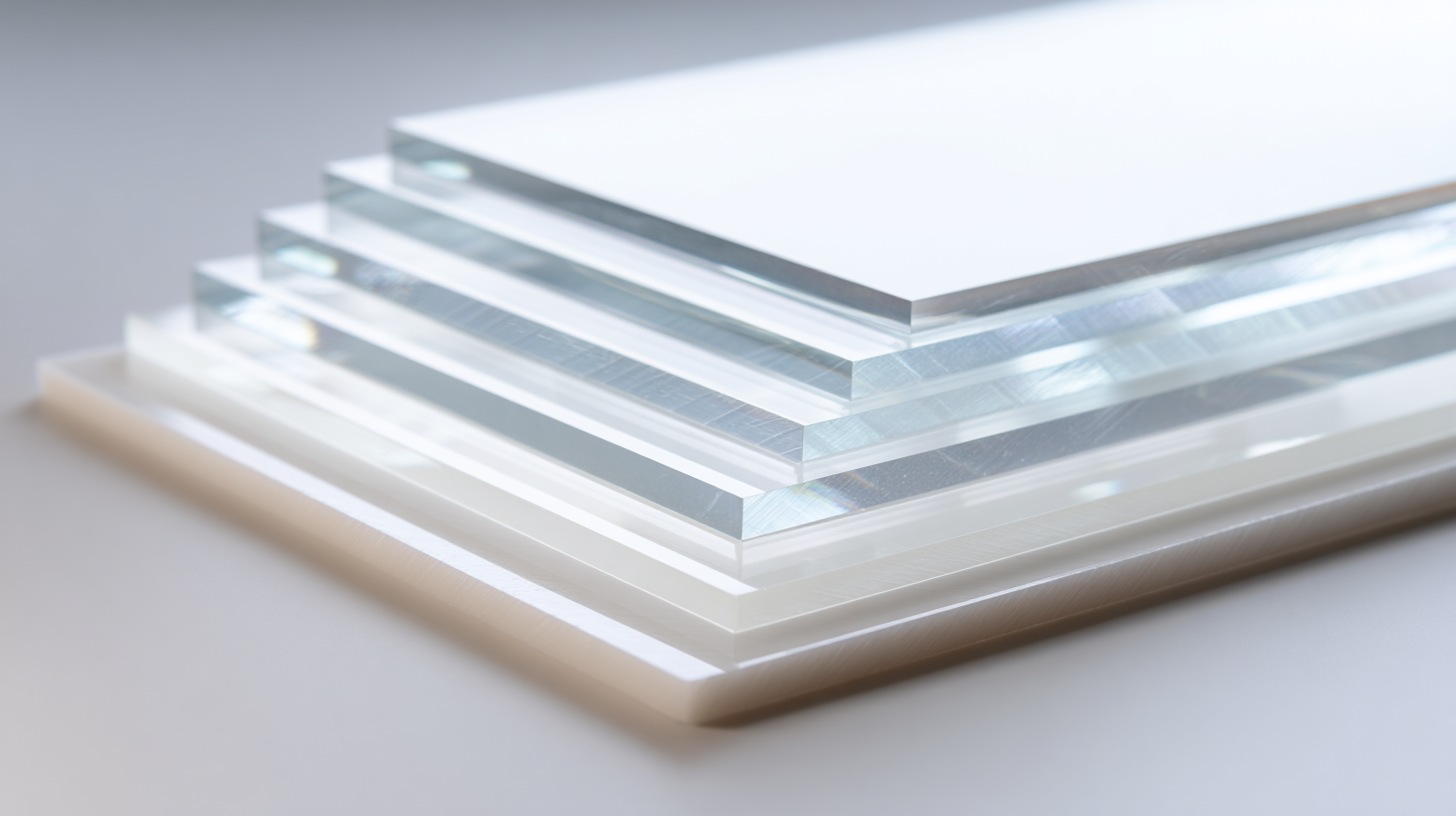

When embarking on a vacuum forming project, selecting the right plastic sheets is paramount to achieving optimal results. Different types of plastic sheets offer unique properties that can significantly influence the final product's strength, flexibility, and aesthetic appeal. Common materials include ABS for its durability, PETG for its clarity and ease of thermoforming, and HIPS for its low cost and ease of printing. Understanding the specific requirements of your project will guide you in making the right choice.

Tips: Always consider the thickness of the plastic sheets, as this can affect the forming process and the detail of the finished product. Thinner sheets are easier to form but may lack strength, while thicker sheets may require more energy to heat and can complicate the forming process. Moreover, look for sheets that have been specifically manufactured for vacuum forming, as these are designed to withstand high temperatures and provide an excellent finish.

Before finalizing your material selection, it's a good idea to request samples. This allows you to test various plastic sheets in your specific vacuum forming setup, ensuring compatibility and helping you identify any alterations needed in your technique. By testing different materials, you can better understand their properties and how they react during forming, leading to superior outcomes in your manufacturing process.

Essential Equipment and Materials for Efficient Vacuum Forming

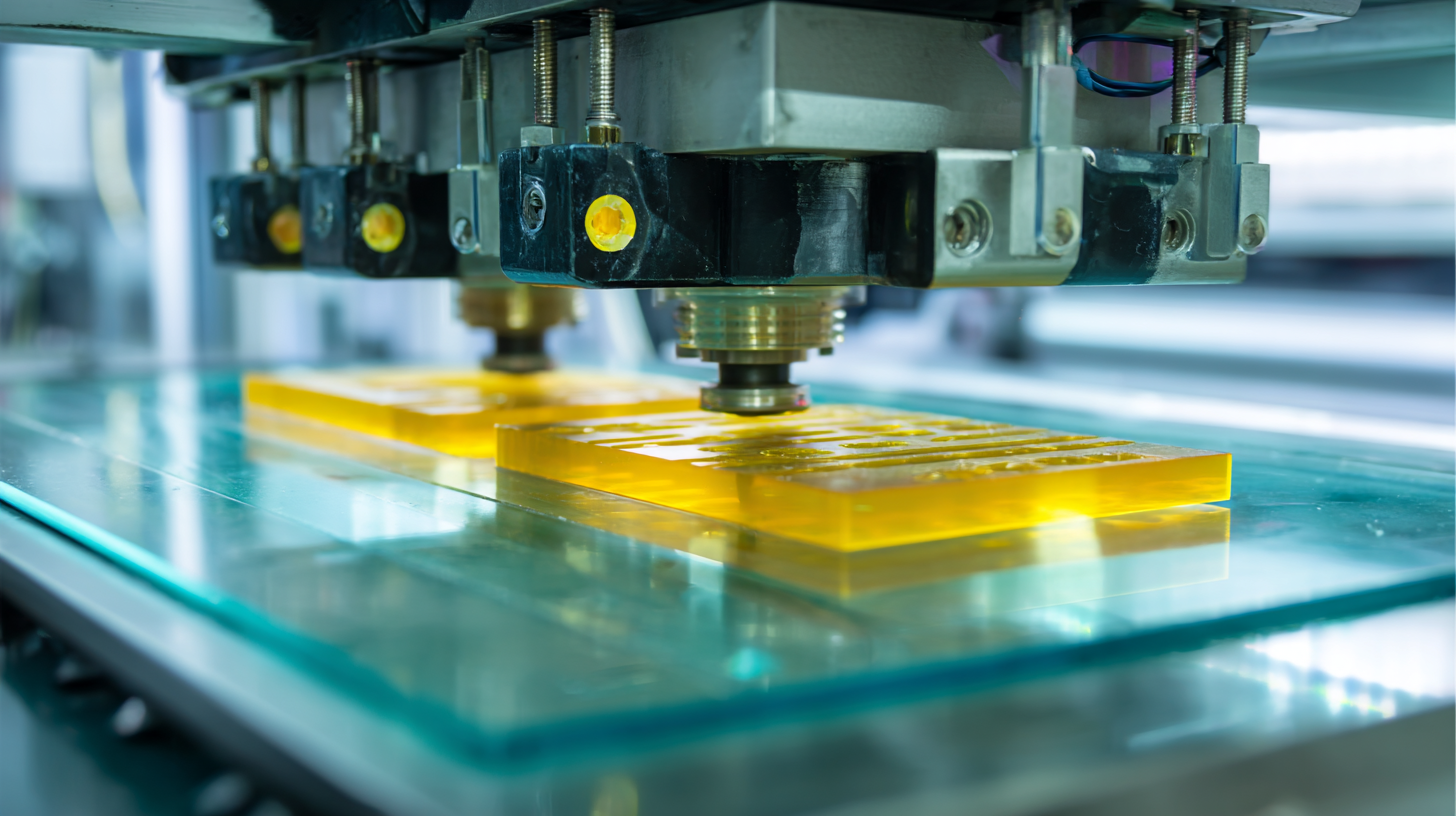

When utilizing vacuum forming for manufacturing needs, understanding the essential equipment and materials is crucial for achieving optimal results. At the core of the vacuum forming process is the vacuum thermoforming machine, known for its ability to transform plastic sheets into complex shapes efficiently. These machines operate on the principle of heating plastic sheets until they become pliable, followed by the use of a vacuum to conform the heated material to a mold. This method not only enhances the precision of the final products but also reduces waste, making it a desirable choice for cost-effective manufacturing.

**Tips:** When selecting materials for vacuum forming, consider lightweight and high-strength options that offer durability and thermal stability. Advanced polymers can be particularly effective, as they ensure the integrity of components designed for diverse industries, from automotive to medical packaging. Additionally, it's essential to invest in quality molds, as accurately designed molds will enhance the overall efficiency and quality of your production process. Adopting innovative techniques such as computerized modeling can further streamline the design and manufacturing workflow, leading to better resource management and reduced production times.

Vacuum Forming Material Usage in Manufacturing

Step-by-Step Guide to the Vacuum Forming Process

Vacuum forming is a widely adopted manufacturing technique used to create durable plastic parts by shaping plastic sheets over a mold using vacuum pressure. The process begins with heating a thermoplastic sheet until it becomes pliable. According to a report by Smithers Pira, the global market for vacuum forming is expected to grow at a CAGR of 4.5% over the next five years, driven by the increasing demand for lightweight components in various industries including automotive and electronics.

Once the sheet is heated, it is quickly placed over a mold and the vacuum system is activated. This forces the plastic to conform to the mold's shape, creating a precise product. Industry data indicates that vacuum forming can achieve production rates of up to 900 units per hour, significantly enhancing efficiency compared to traditional manufacturing methods. It's essential to consider factors such as material choice and mold design, as they can greatly influence the quality and cost-effectiveness of the final product. Understanding these elements enables manufacturers to optimize their operations and meet the specific needs of their clients efficiently.

Common Challenges in Vacuum Forming and How to Overcome Them

Vacuum forming is a popular technique in manufacturing, but several common challenges can hinder its effectiveness. One of the primary issues is achieving uniform material heating, which can lead to uneven forming and structural weaknesses in the final product. To address this, manufacturers should invest in high-quality heating systems that allow for precise temperature control across the entire sheet. Regular maintenance and calibration of heating elements also play a crucial role in ensuring consistency, thereby enhancing product quality.

Another challenge faced in vacuum forming is maintaining the correct level of vacuum pressure. Insufficient vacuum can cause incomplete forming, while excessive pressure may distort the material. To overcome this, it is vital to monitor and adjust vacuum levels throughout the process based on the specific requirements of the material being used. Implementing automated pressure control systems can streamline this aspect, providing real-time adjustments and enhancing efficiency. By focusing on these key areas, manufacturers can significantly improve their vacuum forming processes and achieve better results.

Related Posts

-

Unique Applications of the Best Vacuum Forming Plastic Sheets in Modern Design

-

Future Trends in Best Vacuform Plastic Market Analysis and Examples for Global Buyers 2025

-

How to Choose the Right Plastic Drip Tray for Your Needs

-

Top Strategies for Selecting the Ultimate Spill Tray with Drain

-

Revolutionizing Spill Management The Definitive Guide to the Best Spill Tray Innovations by 2025

-

Discover the Finest Large Shallow Plastic Trays from Leading Manufacturers in China